Robots swear by FEURER

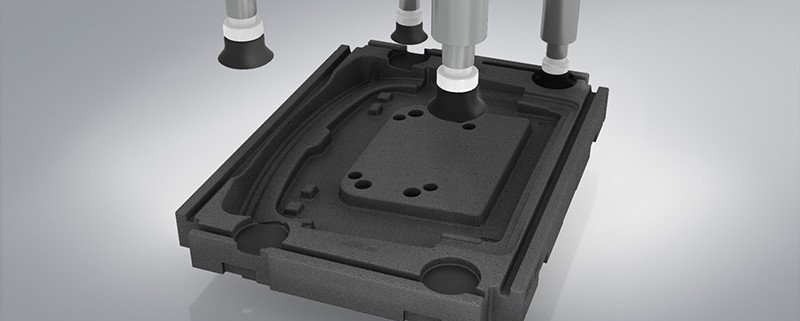

A load carrier as a functional part in automated production – for Mercedes-Benz FEURER has made this vision come true: A load carrier for panoramic roofs has been precisely adapted to the requirements of industrial robots and ensures interference-free processes in automobile production.

Harald Cornet, sales manager in the field of load carriers, has overcome a major challenge for Mercedes-Benz: “The need was for a load carrier that could be drawn in by a vacuum by industrial robots. For this, the robots need completely smooth contact surfaces for their suckers.” The surface of EPP carriers tends to be rather rough. With fatal consequences: “If a robot could not reliably lift the load carrier, the belt stood still at first,” Cornet recalls. “Even glued-on plastic sheets were not stable enough over the long run.”

Cornet found the solution in another FEURER business segment. “Our colleagues from the Packaging Division developed a new technology for the KÄNGABOX® Thermobox programme in order to give EPP a smooth skin.” Cornet has now made use of this method for the first time for the automotive industry.

The industrial robots were not the only factors that needed to be considered in the development. In cooperation with Mercedes-Benz, FEURER adapted the load carrier to the panorama roofs while complying with extremely narrow tolerances. In addition, the efficiency was improved during transport. This means that ten instead of the previous nine panorama roofs can be transported with a robot-compatible load carrier on an undercarriage.

The solution works so reliably that it has been adopted by other Daimler plants. After Bremen, the robots in Sindelfingen and – in the near future – Rastatt will be relying on these load carriers made by FEURER.