ONE NAME, UNLIMITED OPTIONS

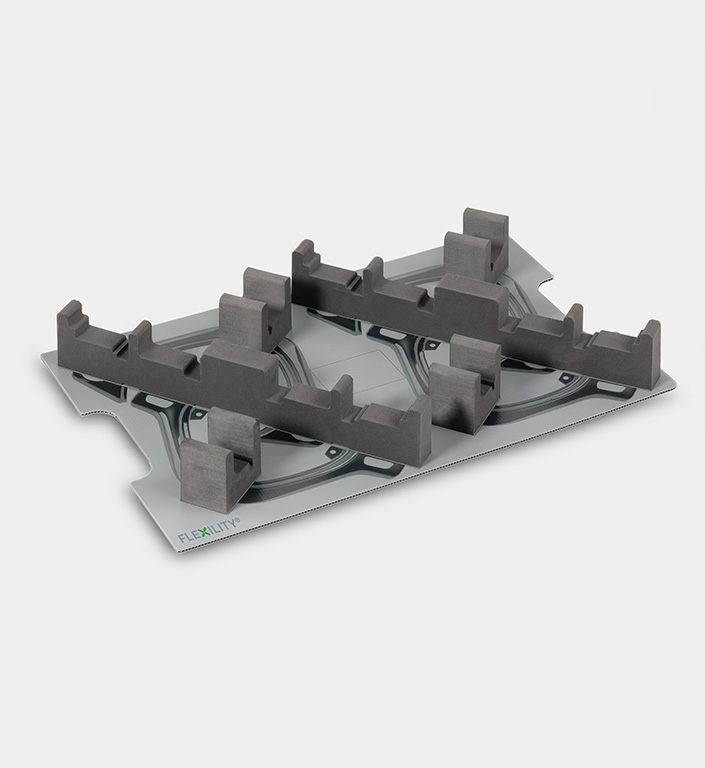

Our new series of special load carriers goes by the name FLEXILITY® and that already says what it’s all about: We combine different technologies for individual requirements. This allows unique flexibility to meet a wide range of component transport challenges in the automotive industry.

The sooner, the better

Ideally, we are already involved in your project during the component design phase. As specialists of many years’ standing, we know the requirements and problems very well and can lend you proactive assistance. We often have ideas and solutions ready before our customers even know that they are needed. Whether it’s about cutting CO2 emissions, reducing volume or weight, ensuring the safety of your most sensitive components or optimising all processes related to transport – you can rely on our expertise.