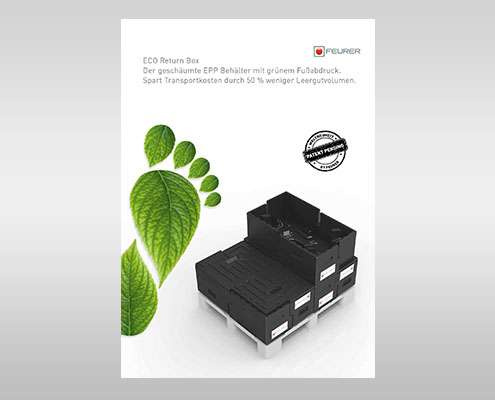

ECO Return Box – The SLC with the green footprint

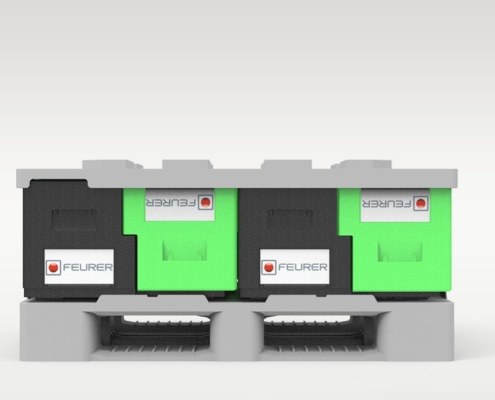

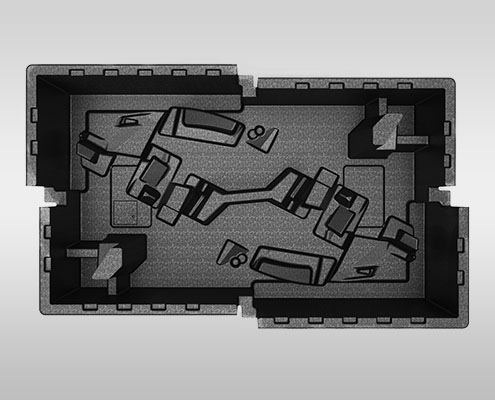

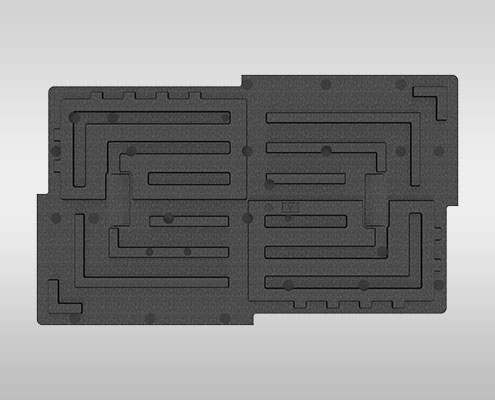

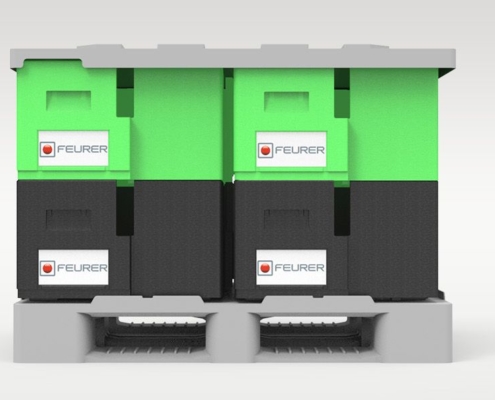

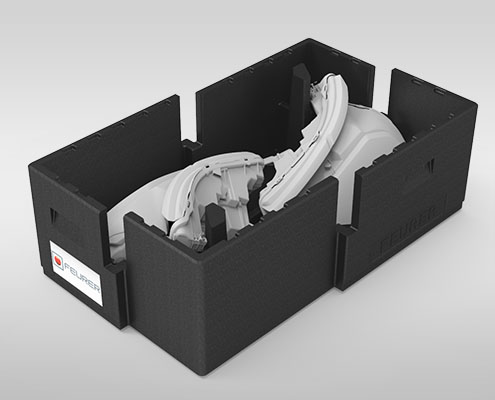

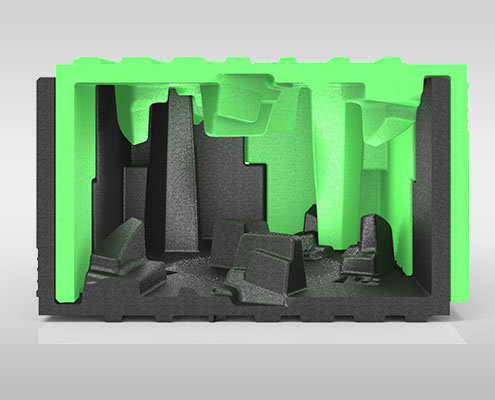

The ECO Return Box SLC is a stable, handy reusable special load carrier made of EPP. With convincing advantages in empties logistics and the best result in the total cost balance of load carrier concepts. Two containers nest completely into each other and thereby achieve a volume reduction of 50 percent. And all this with a single twisting movement from the wrist. Thanks to sophisticated interlocking and base form structures, there is no need to strap the empties. The SLC stand on a pallet and do not need a mesh box.