EPP recyclate – For even more sustainability in reusable logistics

We focus on sustainability and use EPP recyclate in foamed containers and moulded parts. In this way, we consume less virgin material, use existing resources and reduce CO2 emissions. All the positive properties of EPP are retained, i.e. moulded parts and load carriers are as stable, light, shock-absorbing and temperature-insulating as usual. In crush resistance tests according to DIN EN 55440-1 and dimensional accuracy tests, the material meets all requirements. We mix the recycled material with virgin material in a proportion of 30 percent. This is significantly higher than the 25 percent customary in the market. In the near future, we will be producing with a 50 percent share of recycled material.

Our services at a glance:

- Development

- Project management

- Production

- Prototyping

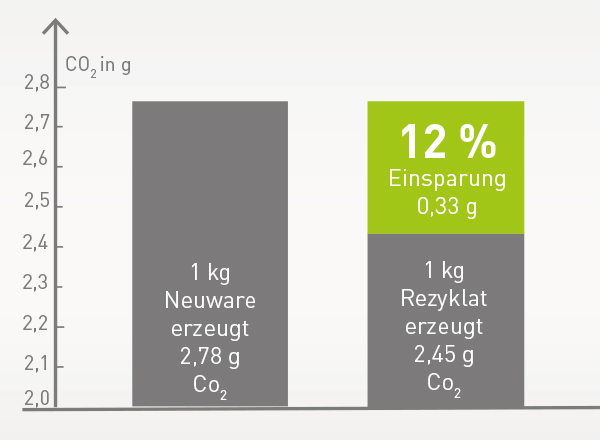

CO2 savings with EPP recyclate

Compared to virgin material, recycled material produces twelve percent less CO2 during production.

Advantages at a glance:

- One kilogram of virgin material causes 2.78 grams of CO2

- One kilogram of recycled material produces 2.45 grams of CO2.

- Thus, one kilogram of recycled material saves 0.33 grams of CO2.

Special load carriers made of recycled EPP

The ECO ReturnBox, for example, offers two potential savings. On the one hand, savings in the volume of empties and on the other hand, the processing of recycled material. Thus, this model saves CO2 in the production in the material and in the use on the road.

Advantages at a glance:

- Use of EPP recyclate

- Saves empties volume during return transport

Moulded parts with EPP recycled content

As a recyclate, EPP retains its positive properties, such as energy absorption, high strength and low weight. It can therefore be processed just as well into moulded parts.

Areas of application at a glance:

- Automotive construction

- Heating systems

- Ventilation and air conditioning

The end-of-life of used load carriers

Foamed EPP load carriers perform stably and reliably for many years as reusable transport packaging and at the end of life they go back into the cycle for recycling.

Advantages at a glance:

- Reliable until the last day

- 100 percent recyclable

- Processing into new foamed EPP load carriers