Load carrier for glass roofs

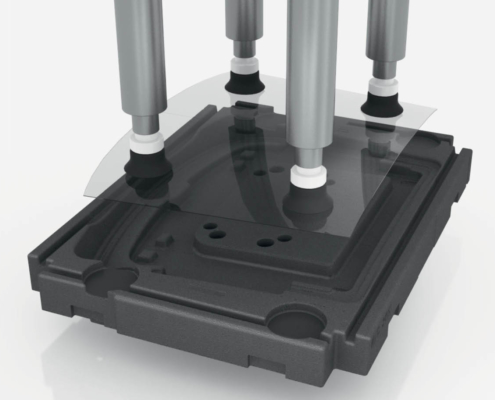

Load carrier for glass roofs for automated production:

Industrial robots first remove the glass roof and then automatically remove the empty load carrier from the stack. For this, they suck in the load carrier by vacuum and displace it. For the suction points, smooth contact surfaces are incorporated in the otherwise rough EPP for suction pickup. The robot can only lift the load carrier reliably with the aid of this smooth surface. This smooth scaling of the EPP is a new development by FEURER which is already used in the KÄNGABOX® (thermal box).

Advantages:

- Fulfills the requirements of industrial robots

- Efficiency during transport: Ten instead of nine panorama roofs fit on one undercarriage.

- Already proves itself reliably in practical usage.

Special load carriers for large two-piece panoramic roofs:

Logistic and assembly of panoramic roofs are a challenge for suppliers and car manufacturers. This special EPP load carrier scores with numerous advantages in transport, storage, and assembly. These include precise filling, exact molding, and the especially homogeneous, water-repellent surface.

Advantages:

- Size XXL for a complete two-part glass roof.

- 1975 x 1325 x 145 mm (L x W x H)

- Both glass roof modules fit into one load carrier

- Insertion and removal by robot

- Weight (empty) of only 15 kg

- Easy and safe handling